![]()

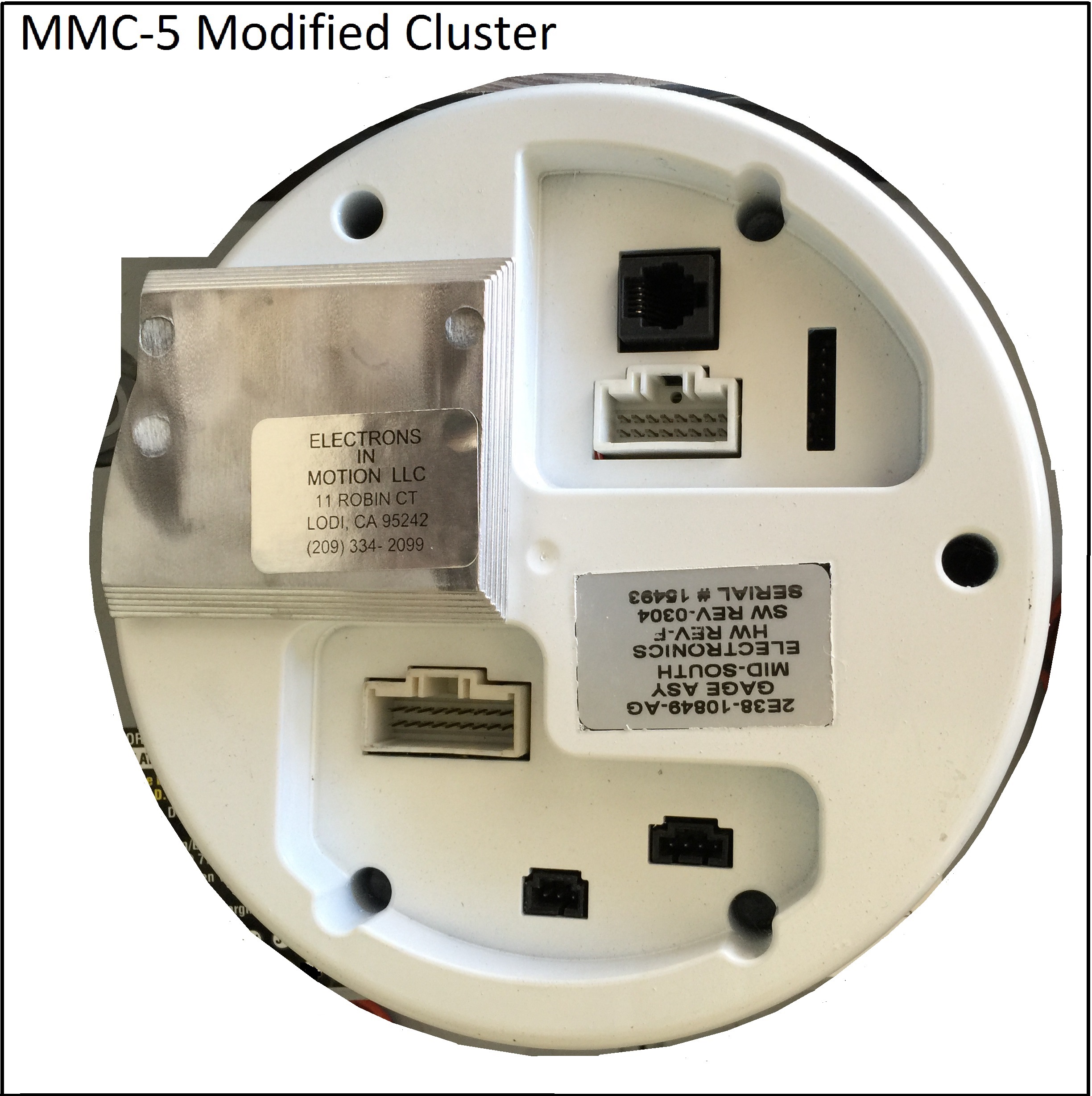

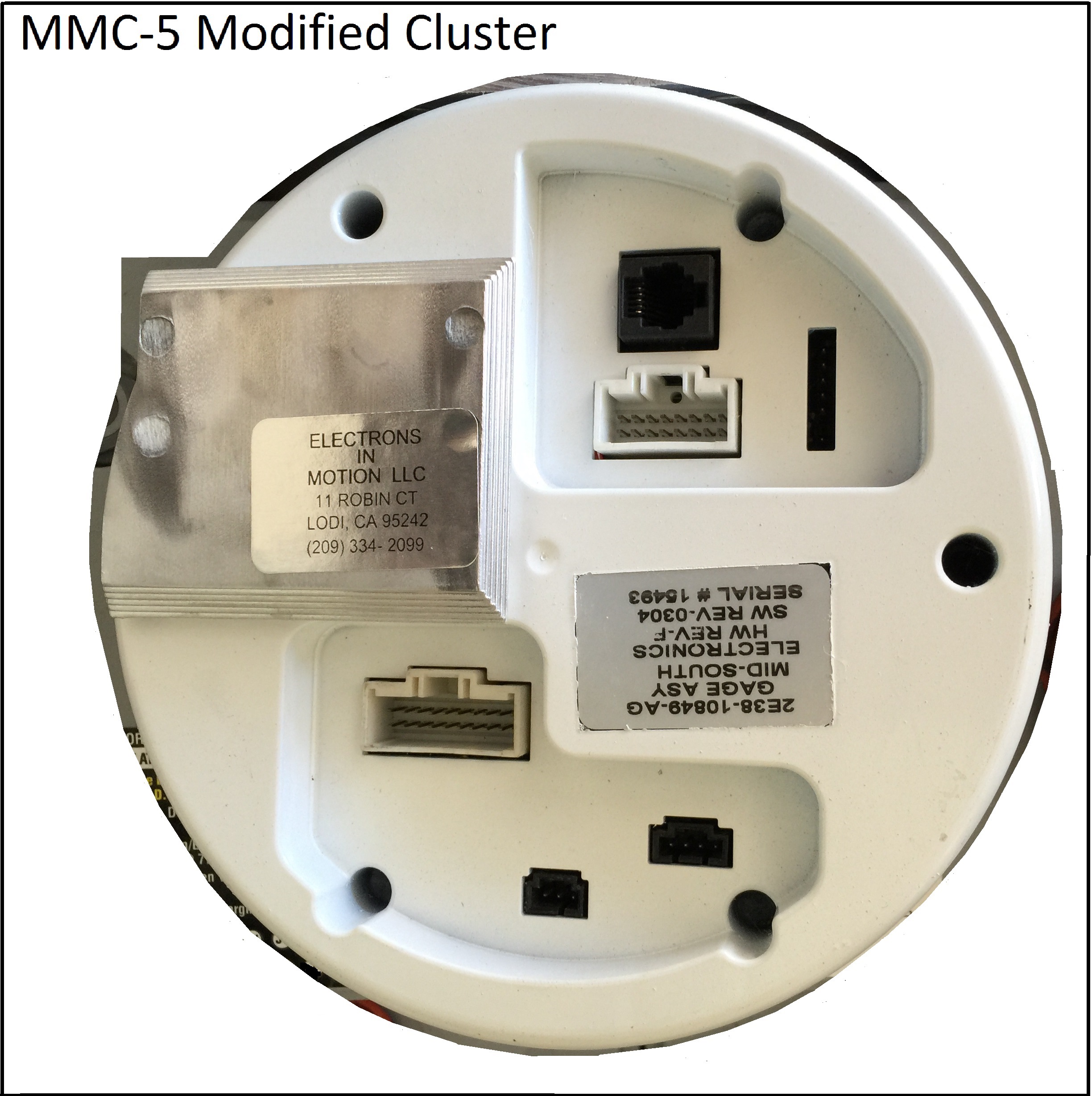

The MMC-5 Modified Cluster consumes far less power than a stock cluster, while providing significantly

increased reliability. It has a limited 1 year warranty.

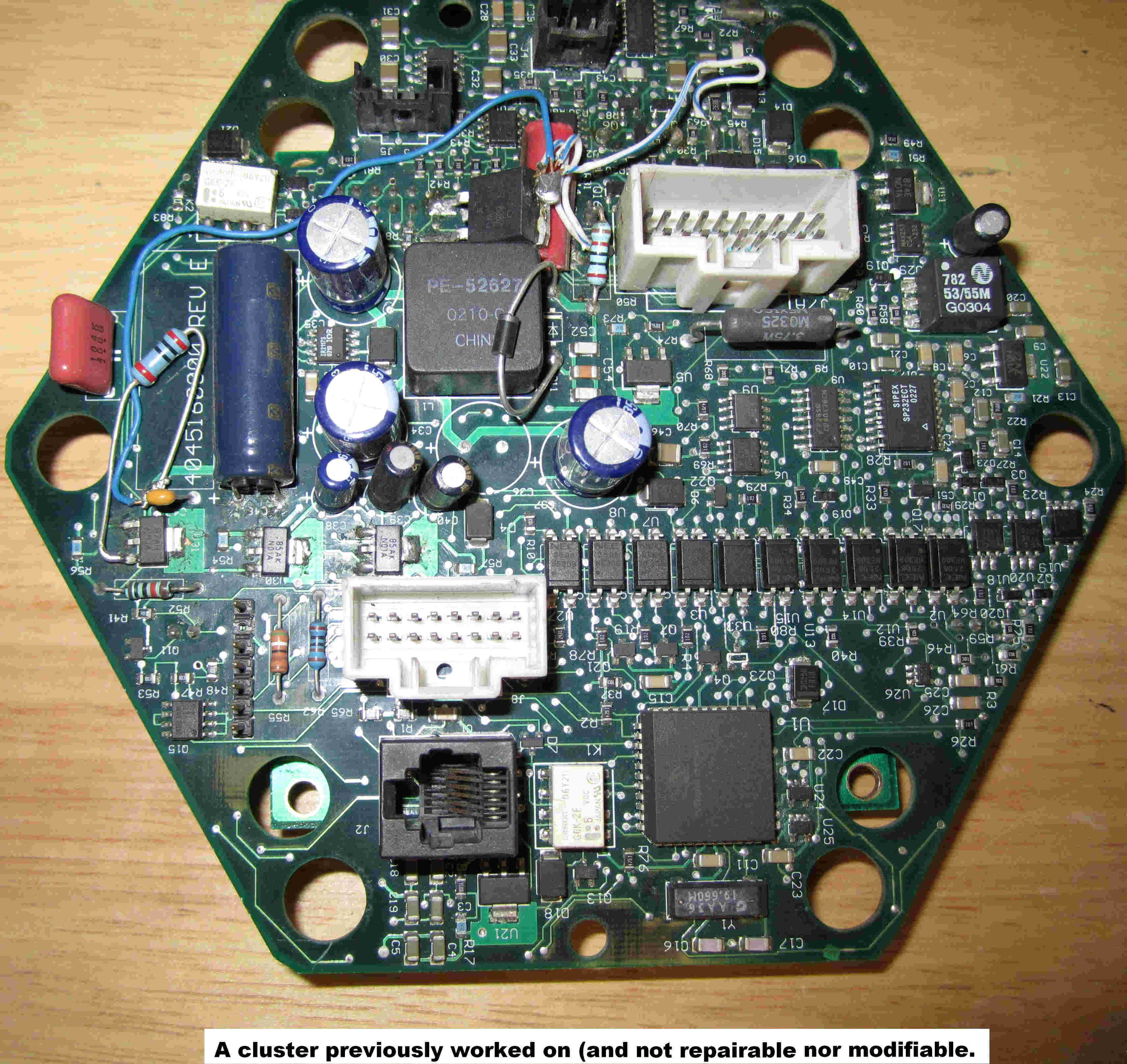

I purchased my 1st Ford Think in 2008, and of course, it had a failed cluster. After replacing it with a new one, I started analyzing and troubleshooting

the failed cluster. I was fortunate in being provided approximately 100 failed clusters to further analyzr failures in the cluster design, and set about

repairing them. The Ford retail price for a new cluster was $360, and I priced my repair costs at a flat rate of $99.00, plus shipping. I also

incorporated some uprated components to improve the reliability of the cluster. Along the way, I started supplying numerous Ford dealerships across the

country, as well as individuals and corporate users. The reliability was improved, but when a cluster failed, it could fail catastrophically, and with

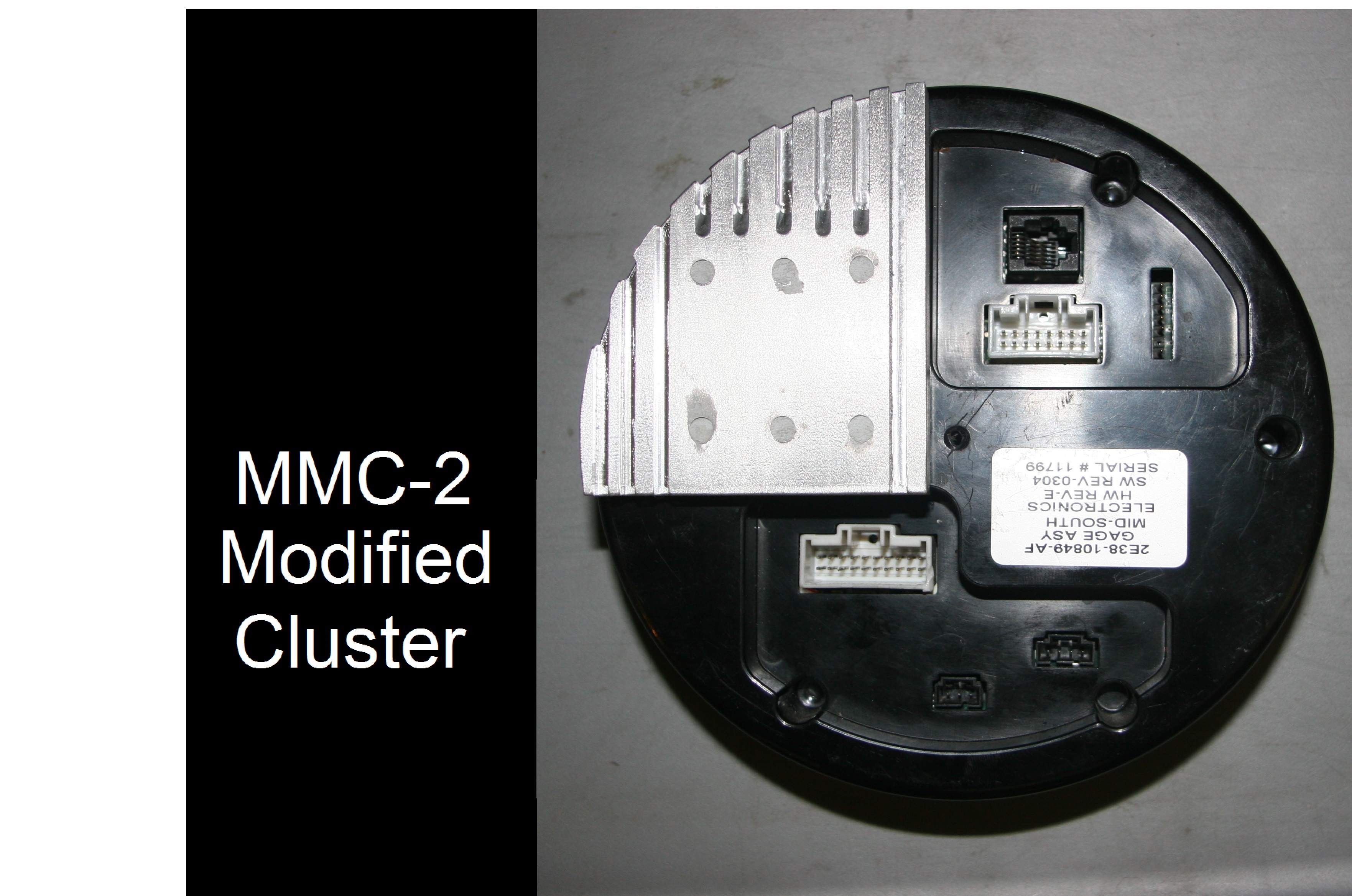

extensive circuit board damage, it could be unrepairable. I continued to look for a better solution, and in May of 2010, I completed months of testing, and

started to ship the MMC Modified Cluster. Subsequently, I have improved the MMC, and have sold 100's of them.

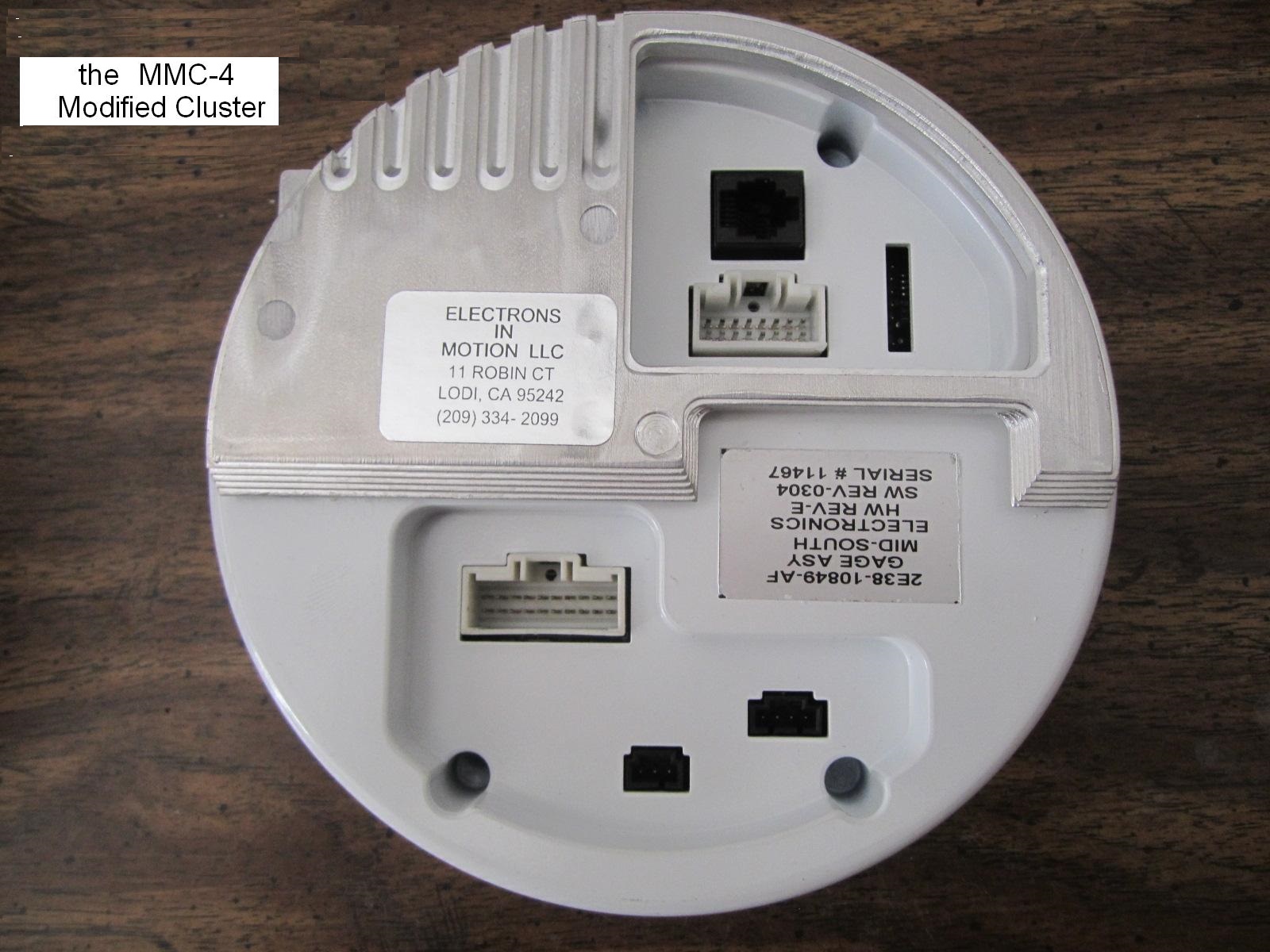

The heart of the MMC has always been a 'Made in The USA' module, made to my specifications. I purchased a CNC mill, and do the milling of the casings and

the custom heatsink for maximum reliability, cluster longevity, and of course, to keep my costs down while retaining flexibility. By using high quality

American made parts, redesigning and custom designing and milling the heatsink, My mission has always been o provide a permanent and cost-effective solution

to keeping the Think on the road.

There are others who have entered the repair (and modification) business. They do sell their repaired and modified clusters on eBay. They also have stated

their opinions on why their units are the best. I won't comment further on their design and implementations, but I decided early on that I wanted a reliable

modified cluster that would be self-contained, easily moveable between Thinks, be 100% functionally identical to the stock cluster, and incorporate any

improvements when possible.

I decided that my first Modified Cluster would have a Low-Voltage Cutout (LVC) feature. This would cause the cluster to flash whenever the cluster would

experience a low voltage condition. This was very beneficial in helping troubleshoot a battery problem, particularly when one or more of the batteries

were the problem. A voltage sag could point to a bad battery. However, putting larger rims and tires on the Think, reprogramming the motor controller

for higher speed, and installing a higher HP motor put a higher power load on the battery pack. Since the standard gel battery pack is still a 72 Volt,

98 Amp/Hr battery pack, but it's being required to provide higher current, the voltage of the pack will sag under the higher current draw, which would

invoke the LVC flashing. This would happen even when tvoe battery pack is functioning correctly, so the LVC feature was discontinued in subsequent

production. The MMC with LVC is still a valuable testing cluster, particularly with a stock Ford Think.

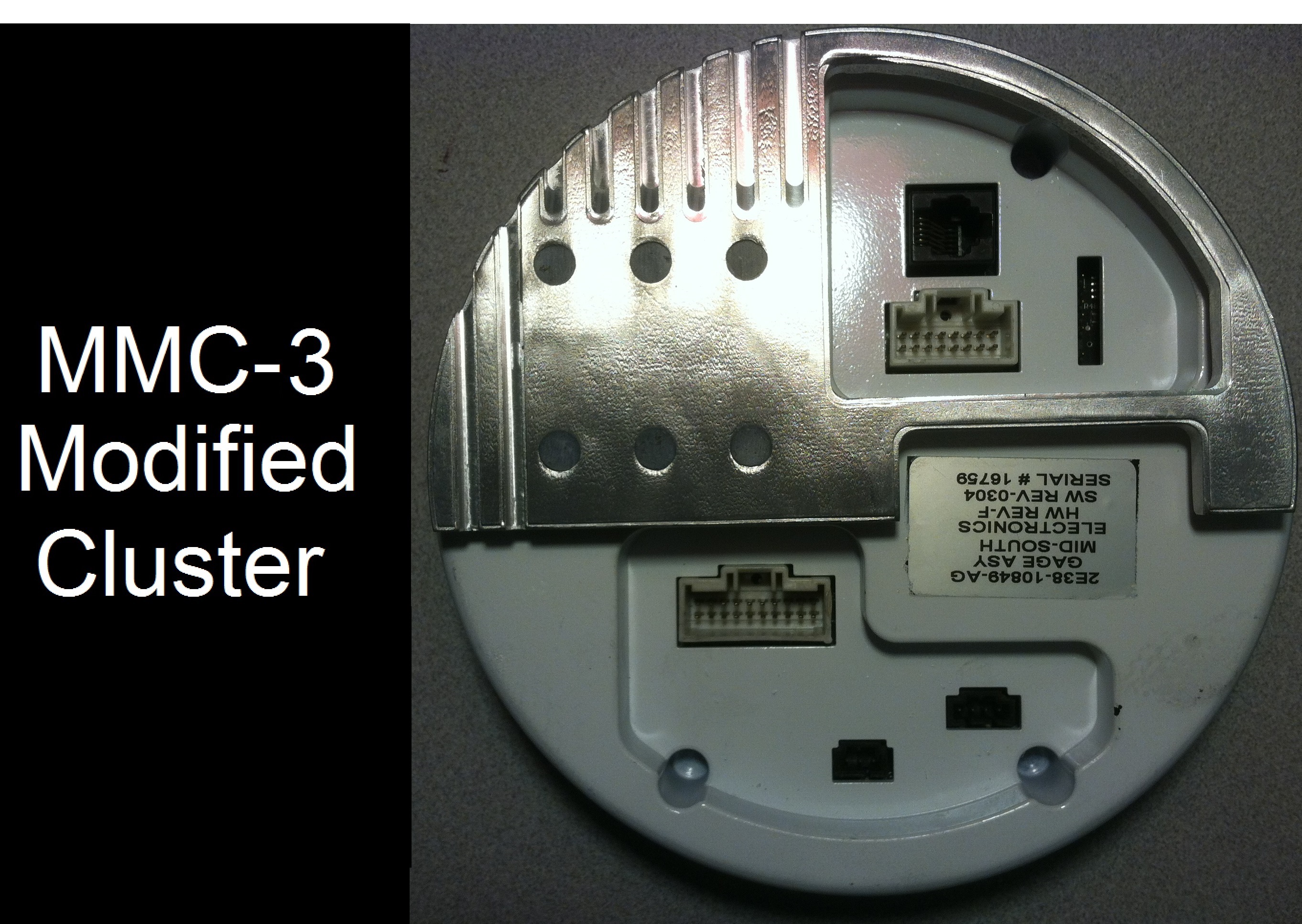

Refined modification and module.

Refined modification and module. Changed Heat Sink design for improved operation (and it looks good!)

This is the latest Modified Cluster. It still operates 100% functionally like the stock cluster, but consumes 25% to 30% less power than a stock cluster.

Since the cluster is drawing this power from the battery pack, and you are paying for every watt of power in the battery pack (when you charge the Think),

this does provice a financial benefit. The old scientific rule of 'Energy can neither be created nor destroyed' just demonstrates that less energy consumed

by the cluster is less energy converted into heat, light, sound, or motion. None of these happen, excedpt for heat, which is dissipated in the cluster.

(If you are thinking, ah, light! The green backlight of the cluster.... No, the backlight gets it's power directly from the Sevcon DC/DC Converter).

I also use premium wire inside the cluster. Aircraft production utilizes Teflon insulated wire, and I use the same Teflon insulated wire as Boeing.

(I know, because my wire is purchased from Boeing Sales).

I design for worst case operational conditions, and my goal is to fix it permanently. I'm not like your typical car dealership, who wants you to keep coming

back for part after part, service after service. I strive to be the permanent fix. That said, I'm happy that quite a few of my previous customers come back

when they buy another Think, or to help a freind or family with their Think.

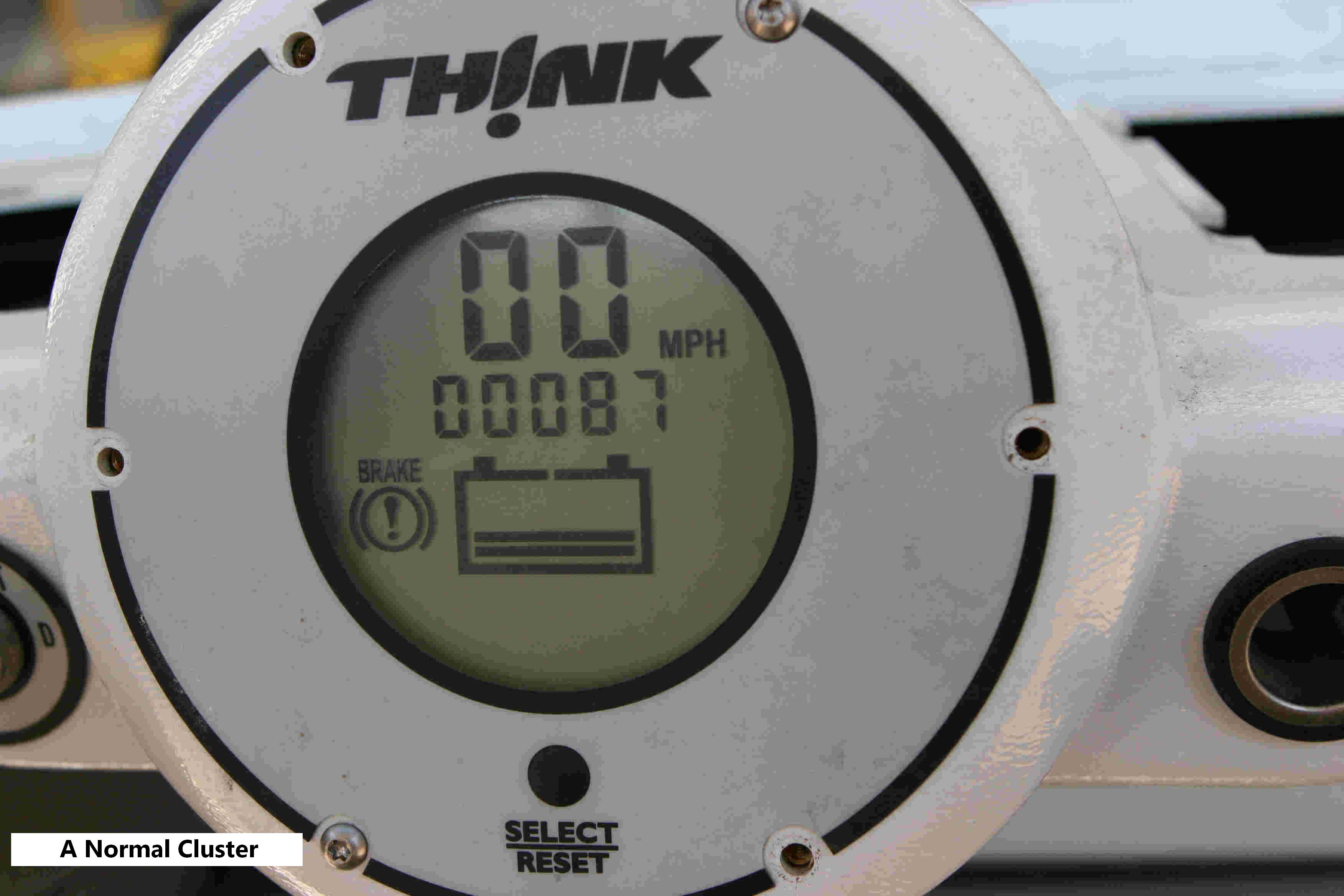

The Ford Think was designed as Ford's answer to the Low Speed Vehicle (LSV) initiative, initially to meet the California Air Resource Board's (CARB)

zero emission vehicle (ZEV) mandate for car manufacturers. The instrument cluster was an integral part of the vehicle, and a inoperative cluster will

prevent the car from operating. While Ford manufactured approximately 7500 of the Ford Think's, based on cluster serial numbers that I have personally

worked on, Ford sold at least 20,000 clusters during the Ford-supported time frame. Ford didn't make the cluster; it was made for Ford by Mid South

Electronics in Gadsden Alabama. The design of the cluster is pretty impressive, but as often the case, what works great in the Research and Development

Lab doesn't hold up in the real world environment.